Out of Stock

Pastel Blue Ceramic cup set (Set of 2)

₹829

₹579

Save 31%

Discover this Ocean Blue ceramic cup set that will elevate your beverage experience at Home. These cups are versatile; they can serve both hot and cold beverages. They are stylish and will enhance the look of your place. These ceramic cups are durable and can be used for a long time. They have a comfortable grip and are ideal for morning coffee/tea rituals.

Buying for a group or event?

Make a bulk enquiry

Product Details

Product Details

- SKU Code: HD_CR_01931_BL

- Art Type : Pottery

- Product : Pastel blue coloured Ceramic Cup set

- Material : Ceramic

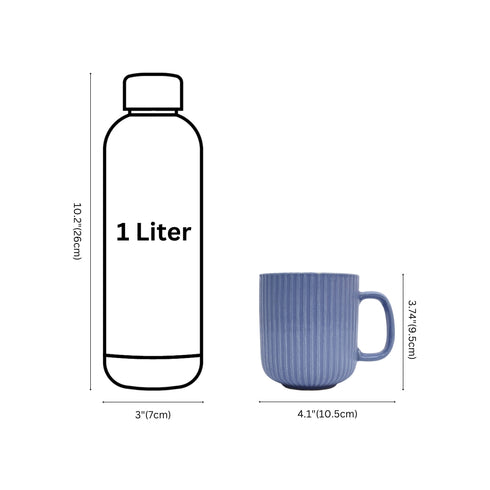

- Dimensions : Length- 10.5 cm, height- 9.5cm, width – 8cm

- Design : Subtle straight lines

- Color : Pastel blue

- Default Title Weight: 430 gms

- Category : Kitchen and Dining

- Sub-category : Serve ware

- Packaging Content : Pastel blue coloured Ceramic Cup X 2

- Country of Origin : India

Features

Features

- Modern design - It has elegant and contemporary minimalistic design in Pastel blue colour.

- Comfortable grip – This ceramic cup set has been ergonomically designed and has a safe and comfortable hold.

- Durability – This cup is made from premium quality ceramic and is suitable for long-term use.

- Multipurpose Use - This cup can ideally be used for coffee, hot chocolate and Tea.

Manufacturing Process

Manufacturing Process

- Preparation of the raw material — In this process, clay is mixed with different materials like Feldspar and quartz to develop a slurry. Then, the slurry uses Plaster of Paris moulds that are saturated with water to develop clay.

- Shaping process: After that, slurry is put into the moulds, and excess is drained. Then, a clay ball is put on a rotating wheel, and the potter tries to give it the shape of a cup by rotating and pulling clay upwards.

- Forming — In slurry casting, the mould absorbs water and forms the cup. During the throwing process, the potter makes the cup's wall and then shapes it while thinning the clay.

- Drying/Firing — After some time, cups are dried and fired in a kiln at a high temperature so the clay hardens.

- Glazing — The glaze is then applied to the cup by spraying or dipping. Later, it is fired to melt so it can create a decorative waterproof coating.

- Finishing – After completing the firing process, cups are checked and customised with designs.

Note

Note

- Avoid using strong cleaners – Don’t use harsh chemicals for cleaning these cups.

- Safe storage – Ensure that the cups are stored in a safe place so there is no chipping.

- Image discrepancies – There can be variations in the images due to screen resolution, so it can look different from the actual product.